Just in time implants

Industry partner

Stryker Australia Pty Ltd

Research organisation

RMIT University

St Vincent’s Hospital

University of Technology Sydney (UTS)

University of Sydney

University of Melbourne

Manufacturing Investment

$17,956,046

($2,999,359 IMCRC)

for 2017–2022

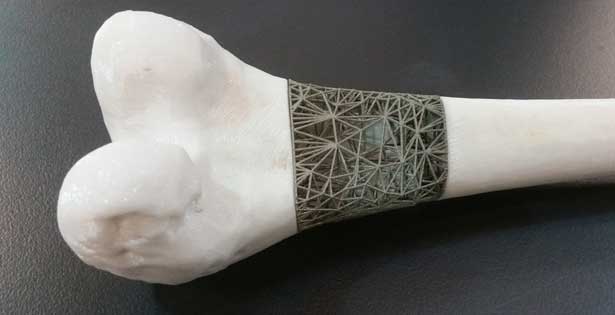

Combining 3D printing, robotic surgery and advanced manufacturing to create just in time tailored implants for patients with bone cancer

Challenge

Manufacturing patient-specific implants is a highly manual and time-consuming process. From osteosarcoma diagnosis to providing a sterile custom implant can take up to six weeks. This increases the risk that a bespoke implant is unable to cope with anatomical changes that present on the day of surgical intervention, rendering them inappropriate for use.

Proposed Solution

Bringing together researchers from RMIT University, the University of Technology Sydney (UTS), University of Sydney, University of Melbourne and St Vincent’s Hospital, the project aims to transform the development and delivery of implants to musculoskeletal tumour patients.

This will be achieved through the development of image analysis and implant design software, combined with precise robotic resection of the tumour. Cutting down the current lead time to produce a solid implant, the custom-made, lattice-structured implants are intended to improve long-term integration with the bone. Robotic removal of the tumour will allow for more exact margins to be achieved, thus reducing the re-occurrence rate of the tumour.

The combined approach will maximise the retention of the patients own bone and soft tissue and decrease the length of hospital stay. It will impact the way prostheses are manufactured and supplied, shifting the paradigm to a local, bespoke setting.