High volume, scalable manufacturing cell for enhanced building products

Industry partner

FormFlow

Research organisation

Deakin University

Manufacturing investment

$900,036

($103,497 IMCRC)

for 2020-21

Controlling the bend

Challenge

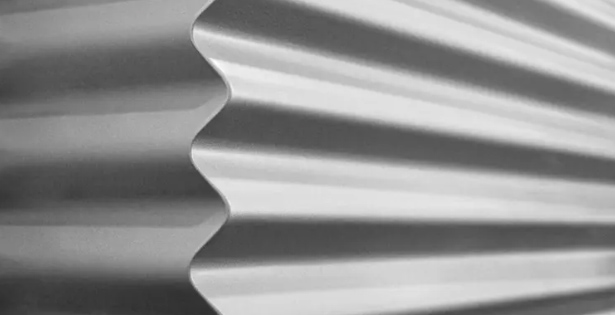

FormFlow’s unique bending technology for corrugated metal sheets has captured strong commercial interest, particularly through producing “tiny homes” and in eco-friendly construction. Investing in Industry 4.0-enabled manufacturing technology and expertise, the company aims to optimise and upscale its production capability.

Proposed Solution

In partnership with Deakin University, FormFlow will establish an Industry 4.0 enabled manufacturing cell equipped with smart vision technologies to trace, evaluate, and continuously monitor forming loads and the profile shape of corrugated steel strips before and after bending in FormFlow’s process.

Metal forming experts from Deakin’s Institute for Frontier Materials (IFM) have already gathered insights into how material flow in FormFlow`s bending process is affected by the incoming profile shape and material properties. As part of the project, they will develop and implement digital solutions that will allow them to model the physical FormFlow process using real-time data and thus establish the correlation between incoming and outgoing profile shapes.

The project represents a vital next step in FormFlow’s technology development and commercialisation journey.