gTET

High-speed permanent magnet rotor post assembly magnetisation and power conversion systems manufacture

Research partner

RMIT University

Total Project Value (AUD)

$478,443

IMCRC Funding (AUD)

$63,494

Start date

01/03/2021

Duration

1.4 years

The shift to renewable energy has seen the sector for clean technology grow rapidly, with the value of the global market projected to almost double between 2016 and 2025 and expand exponentially to 2050. Australian innovators are embracing the change and fuelling the transition.

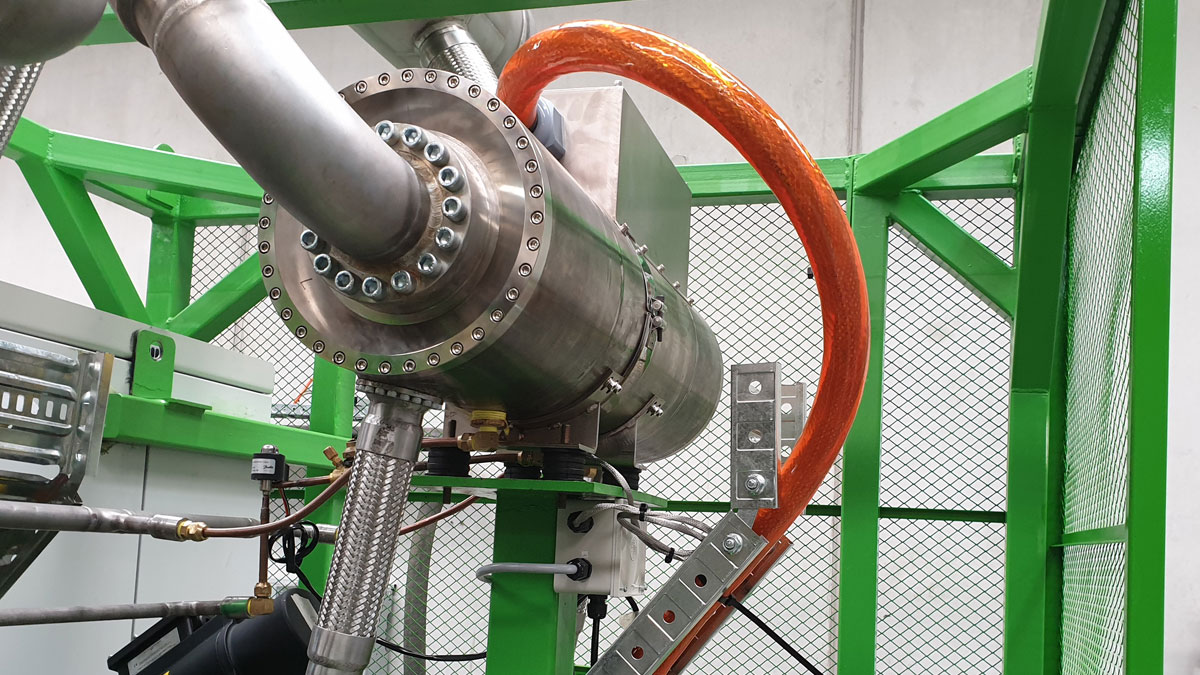

Victorian-based gTET is one such innovator, designing and manufacturing thermal energy efficiency equipment. It’s the only company in Australia, and one of only a few in the world that produces high speed turbo machinery which helps convert solid waste to energy, heat waste to energy and heat waste to heat.

Paul Keen, Managing Director and CEO of gTET, says the company’s core technologies are vital to the clean energy and heat recovery industries and will help companies transition away from gas.

“One of our technologies takes waste heat sources, such as industrial waste heat or renewable heat and generates electrical power from it,” he explains.

“Essentially, it works in the reverse of refrigeration in that we put heat into refrigerant, we drive it through a turbine, and the turbine generates power.

“Our second product is a high temperature heat pump. It’s like a reverse cycle air conditioner, but instead of generating cold it generates heat – up to 150C of heat.

“In the broader context of our net zero targets, electrification and heat, and high temperature heat pumps are a key technology in reducing our reliance on gas.”

In partnership with RMIT University, supported by IMCRC, gTET has designed and developed intricate technical components such as a high-speed magnetizer and a power converter that will allow the company not only advance both technologies but bring some of its manufacturing back onshore.

“Due to the specialised nature of our technology, and smaller volumes, we’ve been importing the turbines however, we’re now in a position to be able to investigate local manufacturing and take greater control of our supply chain.”

Paul and the team at gTET are grateful for the collaboration with RMIT University and IMCRC, citing the financial support as the driving force for the successful delivery of its project.

“If it wasn’t for the contribution from IMCRC, we would not have been able to get to this stage,” he says.

“The process was smooth and streamlined and, overall, very pleasant for us which we really appreciated. The level of technical support from RMIT was excellent and the team’s ability to identify unique parts supply globally surpassed expectations.

“gTET has undertaken several university collaborations respectively since 2010 and all of the outcomes have provided significant value. We would certainly recommend a collaborative research approach to other businesses as a cost competitive method to drive innovation.”

Without the support of IMCRC, we would not have had the financial means to undertake this project. The integration and support throughout has been incredibly valuable to us.

Paul Keen

Managing Director and CEO, gTET