Additive in Australia: What the innovators and researchers from down under are bringing to the industry

“Australian companies have to be very smart…”

A debate in the TCT Group office about which part of the world had the greatest rate of growth with regards to additive manufacturing (AM) brought up several different answers. The U.S., Mainland Europe and China were all, as you might expect, offered up. Without delving into the numbers, it’s hard to pick a definitive winner. For sure, though, it isn’t Australia.

But what of the Aussie innovators and OEMs in the 3D printing space?

The country, though among the largest in terms of land mass, is isolated from the rest of the world. Nearly every flight is long haul, and even within the country itself its largest cities are so spread out it can take up to a day in the car to drive between them. Additionally, it hasn’t a standout industrial sector, and the end of car production in the country earlier this year takes a way many obvious applications of AM technology.

It has traditionally been the universities of Australia to make the initial plunge and invest in emerging technologies. It was much the same with additive manufacturing, and by conducting research and showcasing the capabilities of the processes, it has enticed commercial players and given them the chance to try before they buy.

“I think that’s really important with new technologies that you can, for manufacturers, make something that’s a bit of an intangible concept into something that is really tangible,” says David Chuter, the Managing Director and CEO of the Innovative Manufacturing Cooperative Research Centre (IMCRC) in Australia. “One of the great things about the digital technologies is 3D printing and additive manufacturing very quickly enables people to realise how the digital world can be transformed into something physical.”

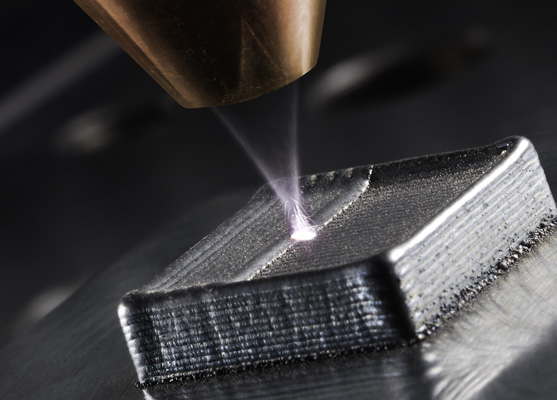

The IMCRC is an organisation ‘doing its bit’ to catalyse investments in new manufacturing technologies. It takes funding from the Commonwealth government and the federal government of Australia to support research projects that have the potential for significant impact. Recently, it contributed $2.36m into a project which will combine 3D printing, robotics, data analytics and advanced materials in a bid to transform how patient-specific implants are made. It has also offered its support to a metal 3D printing facility at the University of Adelaide.