FormFlow and Deakin to commercialise two Industry 4.0 innovations for steel forming

Transforming quality control and delivering new commercial solutions for the steel forming industry

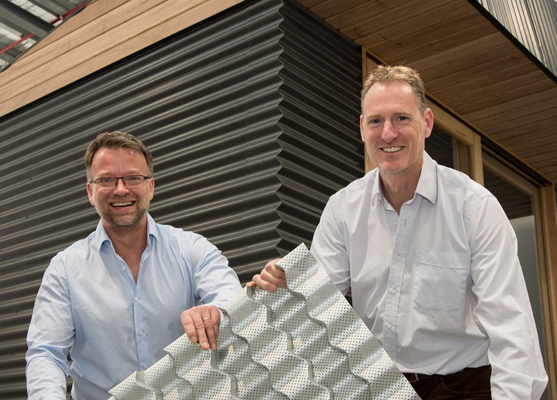

Geelong manufacturing start-up FormFlow and Deakin University have successfully concluded a research collaboration with outcomes delivering new commercial solutions for the steel forming industry.

The project, supported by IMCRC, was designed to establish an Industry 4.0 manufacturing cell to control and optimise FormFlow’s corrugated steel bending process.

However, while undertaking fundamental research into the solution, the project team identified additional outcomes that would deliver greater efficiencies.

The first is a 2D laser system that monitors the cross-sectional shape of sheets before and after bending and enables the manufacturer to perform continuous quality control. The second is an Industry 4.0 manufacturing cell capable of producing a corrugated corner bend from a flat sheet of steel.

Matthias Weiss, Senior Research Fellow at Deakin University, said having the flexibility to adjust the scope of the project enabled the team to develop completely unexpected, but more effective, solutions.

“Our research still focused on creating a high-volume manufacturing cell, but instead of implementing equipment to monitor and control the bend, we designed a new technology and forming process called the in-phase continuous corner (IPCC),” he said.